Plant Cell Culture

PRODUCTION OF ACTIVE BOTANICAL INGREDIENTS

Specialized Supplier of Raw Materials for Plant Cells (callus)

We preserve natural resources through biotechnology,

for the future of people and the planet

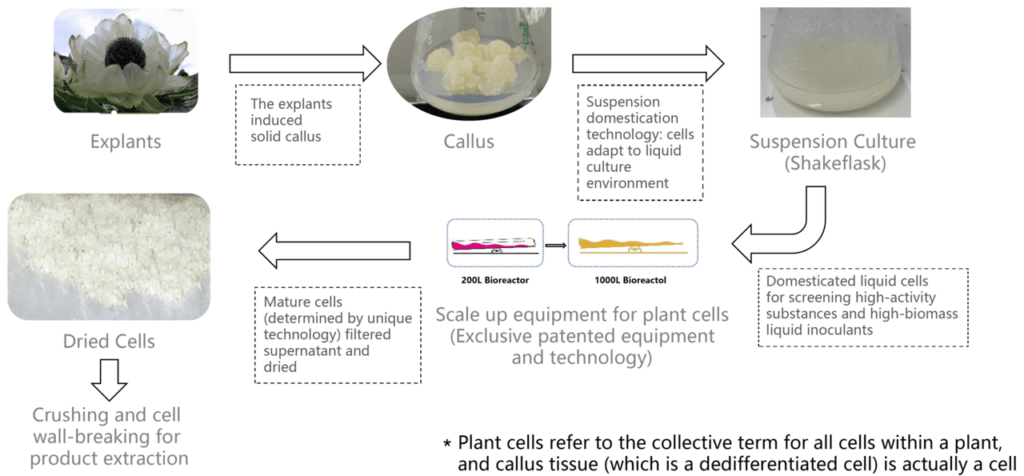

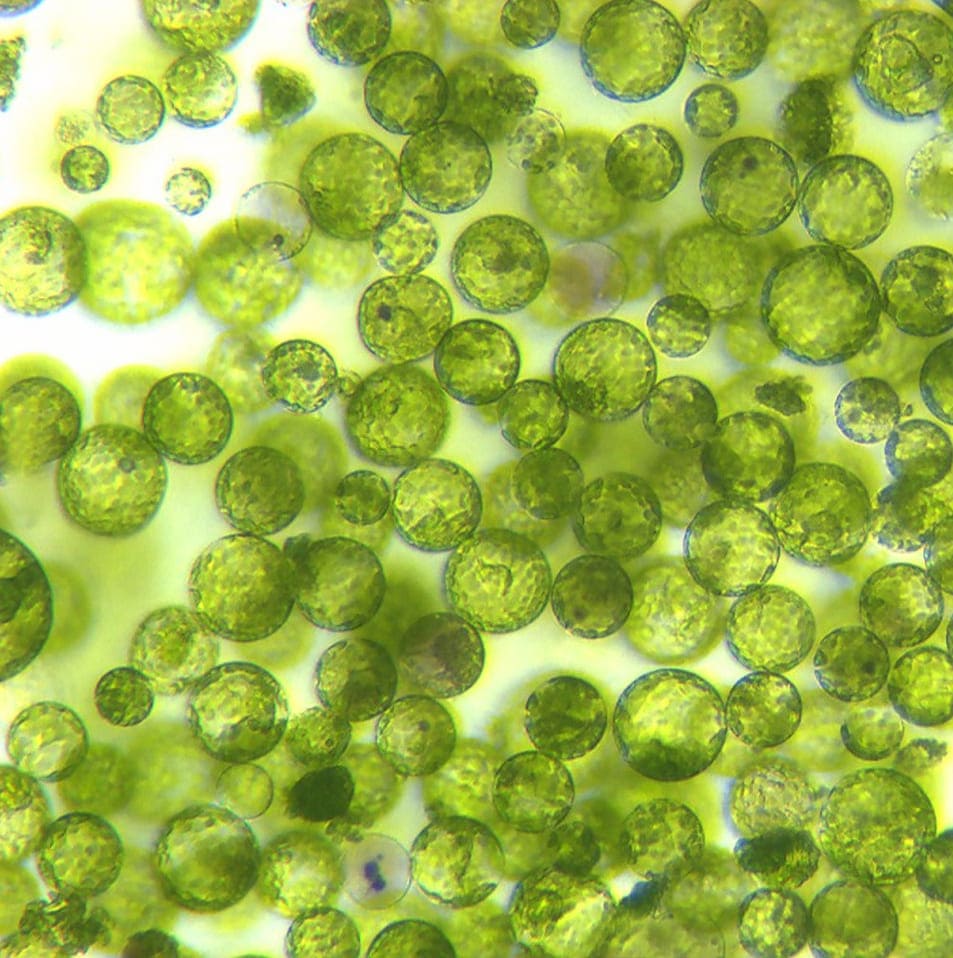

Plant cell culture is a technique conducted under in vitro conditions, where callus tissue or other easily dispersible tissues are placed in a liquid culture medium for suspension culture. This results in the dispersion of cells into free-floating suspension cells, which proliferate through subculture, thereby obtaining a large population of cells. Plant cell culture technology enables the scalable cultivation of plant cells in indoor environments, offering cost advantages, uniform quality, stable supply, and environmentally friendly plant-based materials without the need for arable land.

Callus refers to a rapid-proliferating, non-specifically structured and functional cell mass that forms on the surface of a wound or explant in response to trauma stimulation of a plant organ. It undergoes dedifferentiation through in vitro culture under appropriate culture medium and hormone combinations.

General Application

Hot Selling Products for Pharmaceutical Raw Materials

Taxus callus extract

Product Name:TAXUS CHINENSIS callus cultures

Product Form:Plant Cell/Callus Extract

Plant Varieties:TAXUS CHINENSIS

Main Ingredient:Paclitaxel,10-DAB

Taxus callus extract refers to the substances derived from the callus (a type of plant tissue) of the Taxus species, which includes trees and shrubs commonly known as yews. The extract has been studied extensively for its medicinal properties, particularly its potential in cancer treatment.

Taxol, also known as paclitaxel, is a potent anticancer drug. It is an extract of the Taxus tree, which has been shown to have anticancer effects. Pharmaceutical companies extract paclitaxel, leaving the poisonous chemicals in yew behind for the treatment of breast and ovarian cancer

Process Flow Show

—– p l a n t c e l l s c a l e p r o d u c t i o n t e c h n o l o g y s y s t e m

Product System

Plant Cell Scale Culture Platform Technology System

Breakthrough in mass production, variety breakthrough and flexible production

Based on the “new technology of integrated metabolic control of biosynthesis and post-biosynthesis ” ②)the “back wave disposable bioreactor ” ③technology pioneered by GUGU, we have formed an internationally leading plant cell scale culture platform technology systemt with completely independent intellectual property rights .This technology system has achieved three difficult technological breakthroughs : industrialized mass production of plant cells (flexible production of 1000 liters per unit), freedom of species (all plant species can be mass produced on this technology platform without restriction)and flexible production④.

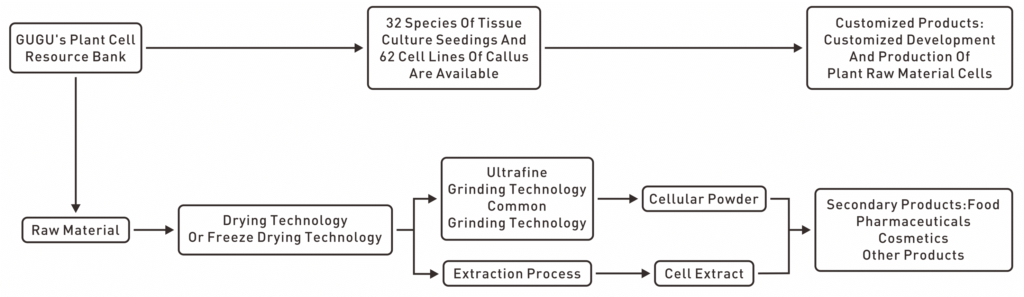

Plant Cell Repository

Exclusive plant cell repository

The plant cell resource bank with unique fingerprint map and unique plant cell induction and domestication technology can quickly obtain high quality,traceable cell seeds;the plant cell scale platform technology system with completely independent intellectual property rights covering the whole production chain of plant sampling,cell line construction,cell culture,induction and regulation,scale culture,extraction and purification,nutrient solution configuration,etc.

Protecting ecological sustainability

- Storage of a large number of cherished, endangered, high- quality plants callus seed sources

- 32 species of tissue culture seedings and 62 cell lines of callus are available and constantly increasing

- Complementary: each cell line can only be mass- produced on the platform of our own patented technology system for large- scale production

Raw Material Category

Based on each type of plant cell raw material,we offer the development of various product forms.

- Water-soluble raw materials

- Oil-soluble raw materials

- Powdered raw materials (freeze-dried, spray-dried)

- Raw materials with cell walls (water-soluble)

- Customized raw materials

Industry-leading Technical Capability

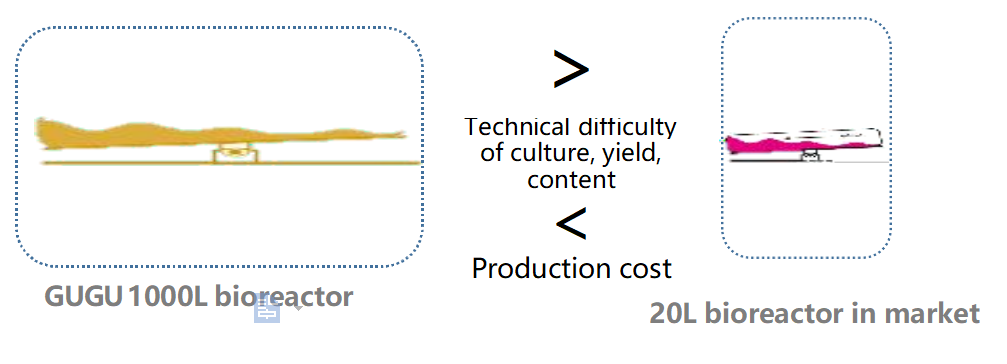

Single-unit mass production capability

- O u r p r o p r i e t a r y p a t e n t e d t e c h n o l o g y s y s t e m h a s t h e w o r l d ‘s l e a d i n g m a s s p r o d u c t i o n c a p a c i t y o f a s i n g l e b i o r e a c t o r.

- O n l y a s i n g l e 2 0 L b i o re a c t o r i s k n o w n t o b e a va i l a b l e i n t h e m a r k e t . GUGU ‘ s ‘B a c k W a v e D i s p o s a b l e B i o r e a c t o r ’ i s c a p a b l e o f p r o d u c i n g u p t o 1 0 0 0 L s i n g l e b i o r e a c t o r s o n a l a r g e s c a l e.

- W i t h r a p i d m u l t i p l i c a t i o n o f p l a n t c e l l g r o w t h a n d h i g h e r y i e l d s o f t a r g e t c o m p o n e n t s , i t r e a l i z e s l o w e r p r o d u c t i o n c o s t s.

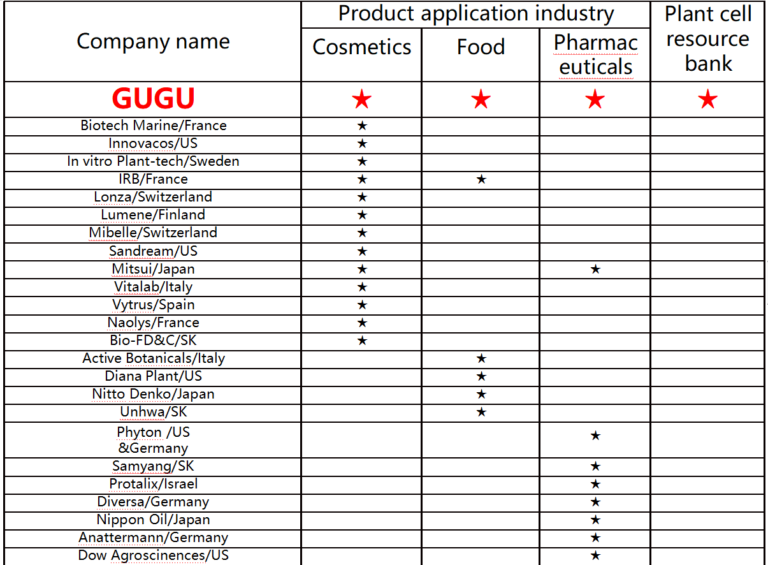

Application areas that can be covered by mass production technology

- Unique technology system for large- scale production of plant cells , which can provide raw m aterials to cosmetics , food and pharmaceuticals .

Technical barriers

Cell line (seed), nutrient solution (fertilizer) and bioreactor(factory) are complement each other

- Unique plant cell resource bank – the cell line with unique fingerprint profile is difficult to be imitated; the unique plant cell induction and domestication technology can quickly obtain high-quality, traceable cell seed source.

- Plant cell scale production technology system – a full set of complete technology system (cell line screening,metabolic regulation, efficient production,analysis and extraction ,etc.)with independently-owned intellectual property rights ;raw materials and culture equipment of nutrient solution used to cultivate cells are both easily available and economical.

- Flexible production system – the unique “wave-back wave” wave-making technology and disposable bioreactor technology can realize the flexible culture and production of plant cell s on a large scale,which is suitable for the market charateristic of small amount and many kind of plant raw materials.

This is Secret

A Brief Self-Nomination,Why Choose GUGU?

GUGU has built the world’s first large-scale C-GMP disposable bioreactor and the plant cell culture R&D and production center,

moreover, it has grown into a global technology leader in plant cell scale culture platform and a leader in cellular agriculture.

laboratory

Reliable Specialized Supplier of Raw Materials for Plant Cells (callus) in China

- Offers the market with low cost, standardized and customizable botanical cell raw materials for cosmetics, functional foods, pharmaceutical compounds and a wide range of other industrial applications

- Realized industrialized mass production of plant cells (flexible production of 1000 liters per unit), freedom of species and flexible production which are the three major technical breakthrough.

- GUGU has an ever-expanding “plant cell resource library” which contains many plant species with high commercial value. It promotes the application of plant cell raw materials in various industries such as cosmetics through strong cooperation with domestic and foreign industry experts

PRODUCTION OF ACTIVE BOTANICAL INGREDIENTS

Why choose the GUGU® Platform

Comparison with agricultural cultivation and competitors of plant cell culture

RESOURCES

- High sustainability and savings in water resources, cultivated area and energy.

- Safeguarding plant species, including rare or protected ones.

- Exclusive plant cell resource repository

- Know-how and professionalism.

PROCESS

- Sterile and controlled environment.

- Full supply chain traceability.

- Industrial scale-up, flexibility and production standardisation,lower cost

- Absence of pesticides, fertilisers, environmental pollutants, substances or products hazardous to human health.

Samples and bulk products can be checked by liquid chromatography to ensure the authenticity of the fingerprints and additional additions from natural plants .

ACTIVE BOTANICAL INGREDIENTS

- High titre product of the active botanical ingredient of interest.

- High-quality active botanical ingredients.

- Extraction of extremely pure, contaminant-free active botanical ingredients.

- Yield independent of seasonality, climatic changes and the plant’s vegetative cycle.

- Stable, standardised and repeatable active botanical ingredient.

We Have Great Answer

Frequently Asked Questions

If your question is not listed, please email us right now.

Taxus callus extract refers to the substances derived from the callus (a type of plant tissue) of the Taxus species, which includes trees and shrubs commonly known as yews. The extract has been studied extensively for its medicinal properties, particularly its potential in cancer treatment.

Taxus callus cultures have been induced using different tissue explants such as seed contents, young stems, and needles. The callus derived from stem segments has shown the best growth in defined media. The culture medium is often supplemented with reducing agents and phenolic-binding compounds. The callus tissues of Taxus cuspidata, for instance, were extracted for taxol after two months in culture and analyzed by High-Performance Liquid Chromatography (HPLC). The presence of taxol was indicated based on UV spectra, peak purity as assessed by photo-diode array spectroscopy, and compared with an authentic taxol as well as by 1H-NMR analysis.

Taxol, also known as paclitaxel, is a potent anticancer drug. It is an extract of the Taxus tree, which has been shown to have anticancer effects. Pharmaceutical companies extract paclitaxel, leaving the poisonous chemicals in yew behind for the treatment of breast and ovarian cancer.

In terms of commercial products, paclitaxel is available as a prescription drug for the treatment of various types of cancer. It is also used in research for the development of new cancer treatments.

axus callus extract is primarily used for the production of paclitaxel (also known as Taxol), a prescription drug that is effective in the treatment of various types of cancer, including breast and ovarian cancer. Paclitaxel works by inhibiting the depolymerization of microtubules, which prevents cancer cells from dividing and thus induces cell death.

Callus culture, also known as callus tissue culture, is a biotechnological method used to cultivate and regenerate plant tissues, specifically callus tissue. Callus tissue is a type of undifferentiated plant tissue with the ability to differentiate into various plant organs like roots, stems, or leaves. This technique is typically carried out under sterile conditions to ensure there is no contamination by bacteria or other microorganisms.

10-Deacetylbaccatin III (10-DAB) is a natural organic compound produced by the Pacific Yew tree (Taxus sp.).It is a key intermediate in the semi-synthesis of Paclitaxel (Taxol), an anti-cancer drug, and Docetaxel and their analogs

Get Started Today!

If you need help finding the right solution to your needs, we’re here to assist.

Let us know how we can help, and we’ll be in touch with the information you need to select the best choice for your needs.

Contact us today and get started on a better way to solve your problem.

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ask For Quote Now!

REPLY WITHIN 24 HOURS