Biosynthesis

What is Biosynthesis?

- Biosynthesis refers to the process by which complex organic molecules are synthesized from simpler precursors through enzymatic reactions in living organisms. These molecules can include proteins, fatty acids, nucleic acids, hormones, enzymes, or other biological macromolecules required by cells.

- Biosynthesis generally occurs within the cell and involves the construction of more complex molecules from simple precursors like amino acids, sugars, and fatty acids.

- This process requires energy, usually in the form of ATP, and is controlled by specific enzymes and metabolic pathways.

Biosynthesis Plant Extracts

| Chinese Name | English Name | CAS Number |

|---|---|---|

| 白藜芦醇 | Resveratrol | 501-36-0 |

| 柚皮素 | Naringenin | 67604-48-2 |

| 二氢槲皮素 | Dihydroquercetin | 480-18-2 |

| 红景天苷 | Salidroside | 10338-51-9 |

| 水飞蓟宾 | Silymarin | 22888-70-6 |

| 淫羊藿素 | Icaritin | 11852-40-9 |

| 淫羊藿苷 | Icariin | 489-32-7 |

| 新橙皮苷二氢查尔酮 | Neosperidin dihydrochalcone | 20702-77-6 |

| 花旗松素 | Taxifolin | 480-18-2 |

Application of Biosynthesis Raw Material

What Do You Need?

Solutions For Every Need

GUGU’s products are built upon a foundation of precise engineering, diverse applications, and a commitment to sustainability and eco-friendliness. You deserve solutions that are as versatile as your needs. We’ve created a line that is right for you, no matter where you are or what you are facing.

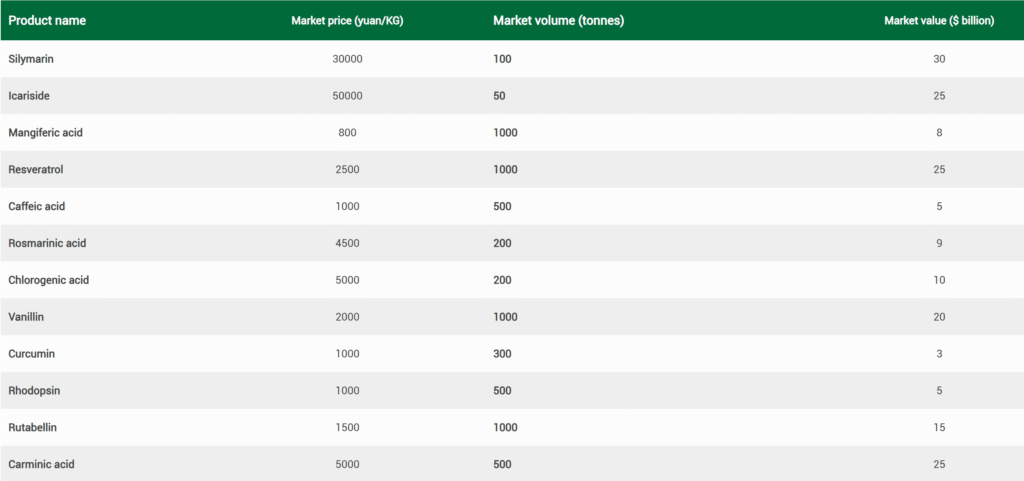

Product Outlook

With growing demand driven by diverse applications across industries, there’s immense potential for expansion. Advancements in precision engineering and eco-friendly solutions enhance the appeal and usability of these products. Continual innovation and adherence to quality standards position these offerings at the forefront of market growth, paving the way for substantial opportunities in various sectors.

This is Secret

A Brief Self-Nomination,Why Choose GUGU?

Offers sustainable and diverse solutions with precise engineering for a range of applications

To be the world's leading practitioner of synthetic biology

The company has formed a strong partnership with the School of Bioengineering at Jiangnan University, establishing a Bio-Joint R&D Center with exceptional capabilities in technological innovation and development. The center is dedicated to the research and production of flavonoid compounds, completing tasks such as strain modification, construction, testing and inspection, small-scale trials, pilot testing, and large-scale production. It has developed a complete product development, production, and sales industry chain. The company has independently established a high-quality flavonoid compound production enterprise, serving the global cosmetics, health products, food, and pharmaceutical industries. The product range includes taxifolin, thymidine, citicoline sodium, resveratrol, and others.

Why choose Biosynthesis?

The variance between biosynthesis and traditional plant extraction lies in their methods and fundamental approaches to obtaining desired compounds:

Biosynthesis:

1.Manufacturing Inside Organisms:

Biosynthesis involves the creation of target compounds within living organisms or through cellular components, such as enzymes or microorganisms. This process can occur within a controlled environment, like a laboratory or a fermentation tank.

2.Engineered Production:

Often, biosynthesis involves genetic engineering or the alteration of biological systems to produce specific compounds or chemicals. This method allows for the production of molecules that might not naturally occur in the chosen organism.

3.Precision and Specificity:

Biosynthesis enables precise control over the creation of compounds, allowing for tailored production of specific molecules or pharmaceutical ingredients with high purity.

Traditional Plant Extraction:

1.Harvesting from Plants:

Traditional extraction involves obtaining compounds directly from plants through methods like distillation, maceration, or pressing. This process often requires substantial amounts of the plant material to extract desired molecules

2.Complexity of Mixtures:

Plant extraction frequently results in complex mixtures, as the extracted substance includes various compounds naturally present in the plant. Purification is often required to isolate the desired molecule.

3.Dependency on Natural Factors:

Traditional extraction methods are influenced by various natural factors like climate, soil quality, and plant growth conditions. This can affect the availability and consistency of the extracted compounds.

In essence, biosynthesis focuses on engineered creation within controlled environments, allowing for precision and tailored production, whereas traditional plant extraction involves obtaining compounds directly from natural sources, resulting in complex mixtures and depending on natural factors for the extraction process.

We Have Great Answer

Frequently Asked Questions

If your question is not listed, please email us right now.

We source high-quality raw materials from certified suppliers and can provide customized precursor substances based on customer requirements. We ensure that all materials meet industry standards and maintain a stable supply chain to ensure the continuity and reliability of the production process.

We use advanced biosynthesis technologies and optimized production processes to maximize production efficiency while maintaining product quality. We collaborate with multiple partners to enhance yield and ensure the best efficiency and cost-effectiveness in commercial-scale production.

We provide comprehensive technical support and continuously optimize production processes to enhance efficiency and reduce costs. Our R&D team works closely with customers to offer personalized process improvement plans, helping them achieve the best balance between product quality, yield, and cost control.

Our production facilities are GMP certified, and all products meet relevant industry standards such as ISO and FDA. We continuously monitor product compliance to ensure that all biosynthesis products meet the regulatory requirements of the target markets. If you have specific compliance needs, we can provide relevant documentation and support.

We provide detailed application data for our products, including clinical trial results and case studies, to help customers understand the product’s efficacy and market potential. We offer relevant research reports and testing data to demonstrate the effectiveness and safety of our biosynthesis products in practical applications.

We strictly control every step of the biosynthesis process, using high-precision testing equipment to ensure product quality and purity. All products undergo multiple tests, including but not limited to purity, activity, and batch-to-batch consistency, ensuring they meet the high standards expected by our customers.

We offer different production plans based on the customer’s needs. While initial costs may be higher, we strive to continuously reduce per-unit production costs through scaling and process optimization. Additionally, we are flexible in adjusting production plans based on market demand to ensure competitive pricing.

Biosynthesis is generally more environmentally friendly compared to traditional chemical synthesis, as it often utilizes renewable resources and generates less waste. We emphasize sustainability in our production process by adopting green chemistry technologies and environmentally-friendly materials, aiming to reduce energy consumption and waste generation.

We conduct stability tests during production to ensure that products maintain their activity and effectiveness under different storage conditions. The specific shelf life may vary depending on the product type and storage environment, but we generally recommend using the product within the recommended storage conditions to maintain optimal performance.

We hold multiple patents for our biosynthesis technologies and will protect intellectual property according to our cooperation agreements. We are committed to building long-term partnerships with our customers and providing transparent solutions for technology licensing and patent protection. If you have any questions regarding patents or technology licensing, we are happy to provide more information and support.

Get Started Today!

If you need help finding the right solution to your needs, we’re here to assist.

Let us know how we can help, and we’ll be in touch with the information you need to select the best choice for your needs.

Contact us today and get started on a better way to solve your problem.

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ask For Quote Now!

REPLY WITHIN 24 HOURS